IKOI Graining Furnace Model Z55 - Gold & Silver - 10kg (to 35Kg Capacity)

IKOI Graining Furnace Model Z55 - Gold & Silver - 10kg (to 35Kg Capacity)

Location:Italy

Description

Plant for the production of gold and silver grains with melting and casting in a cooling tank with protection in a controlled atmosphere.

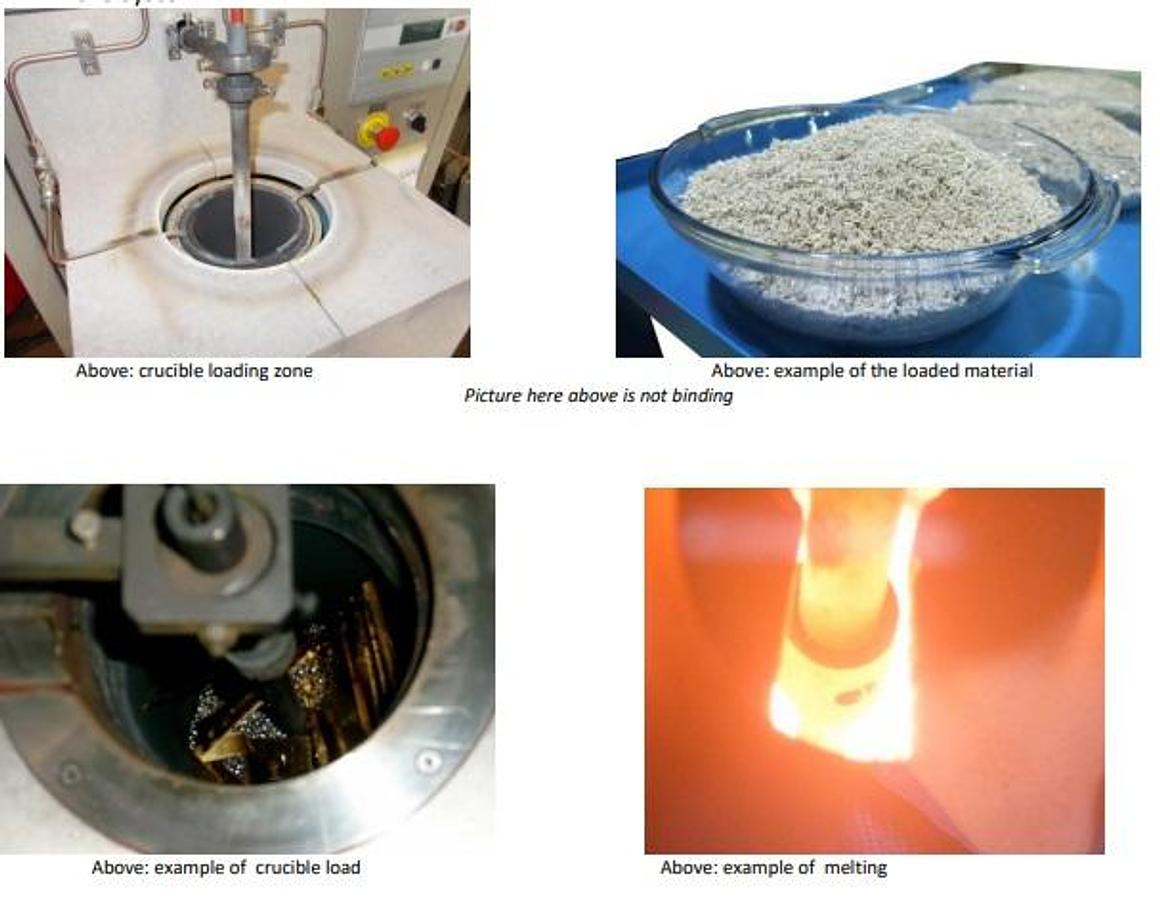

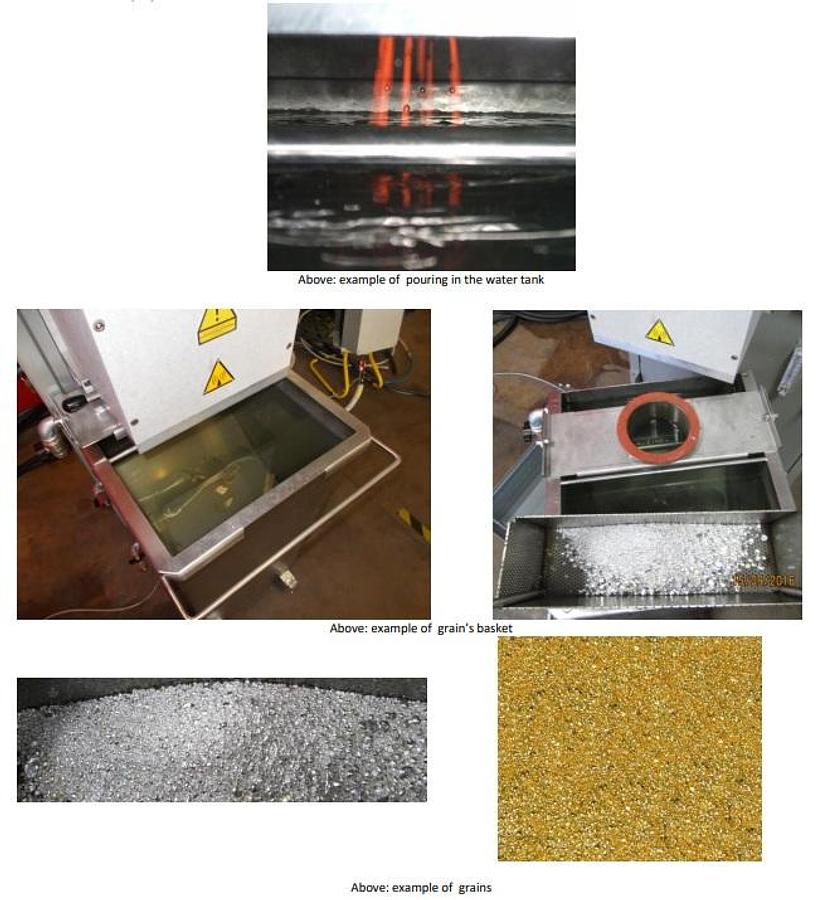

The material to be melted is placed inside a graphite crucible and when the melt is reached it is poured into a tank containing water to create grains.

The crucible is equipped with a pneumatically controlled stopper managed directly by the operator.

A temperature probe detects and monitors the melting temperature.

Melting and casting of the metal in water are carried out in a controlled atmosphere.

From the tank, through a collecting basket, the metal produced is taken manually by the operator.

The machine is equipped with a microprocessor controller for the control and management of the working temperature and of the heating power.

A newly developed electronic power generator allows:

- energy saving by having low losses

- precision in the control of power

- noiseless

- small sizes

The plant is built according to CE regulations.

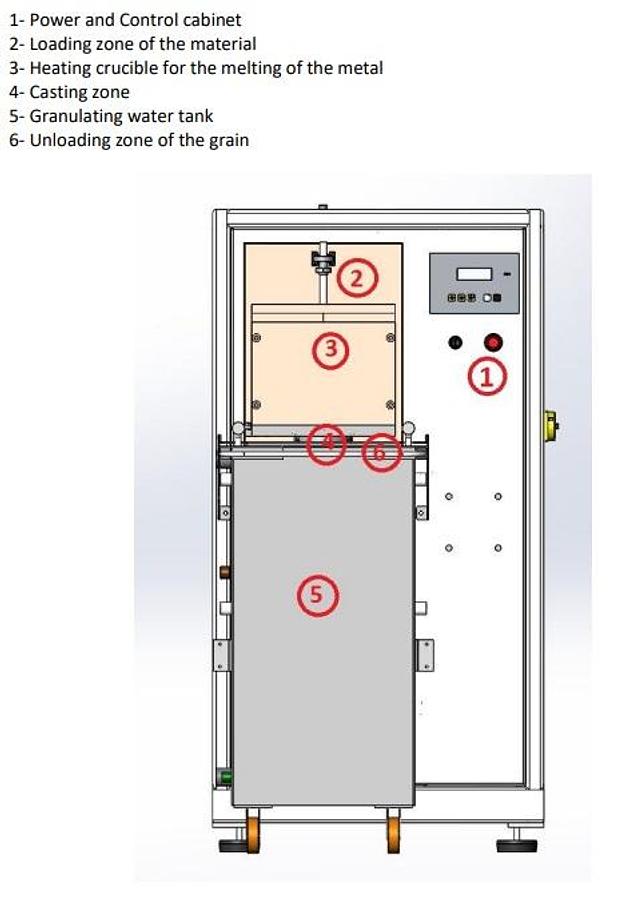

Power and Control cabinet:

- 10 KW medium frequency power generator, made with high quality electronic components, lowleakage passive components, oversized static power components, rigorously tested electronic control circuits

- Passive power components for the resonant induction circuit, composed by medium frequency power low-loss condensers and medium frequency power transformers

- Electric, electronic components

- Control panel with display, from which is possible to control the working parameters:

- Melting temperature

- Real temperature

- Melting generator power

- Real generator power

Loading zone:

- The metal loading area is located at the top of the melting head, and can be reached by lifting the front part of the cover.

Induction melting head with crucible:

- Melting head in insulating material

- Crucible closing lid

- Graphite crucible for melting metal with appropriate insulation in ceramic material and external

- jacket for maintaining the temperature

- Heating inductor

- Crucible and metal protection gas injectors.

- Regulation with flow meter of Nitrogen gas protection flow

- Manual regulation of the LPG protection gas

- Safety guillotine at the base of the melting head

Casting zone:

- Graphite die with holes for the passage of liquid metal

- Removable die from the crucible

- Closure stopper of the die with pneumatic control

- Melting temperature reading thermocouple inserted in the closing stopper

Granulating water tank:

- Stainless steel cooling tank

- Tank capacity 130lt

- Manual collection basket for produced grains

- Removable tank installed on wheels with interlocked presence sensor for easy cleaning

- Arrangement for recirculation pump connection

Unloading zone:

- The grains collection basket is lifted manually and the material produced can be removed from

- the system.

Note on the gold powder which is fed the crucible of the graining machine:

The gold powder which is fed with the crucible of the graining machine must be washed, rinsed and dried in a way that when placed inside the crucible is free of moisture. The value of maximum humidity content in the powder should be of 1.0% max.

Instructions Manuals

- Complete manual will be provided covering following aspects:

- Complete installation schematics and instructions.

- Operational details.

- Mechanical and electrical schematics, wire diagrams, water diagrams.

- Maintenance manual with parts replacement data and troubleshooting details.

- Manual will be in English language

- Use and Maintenance Manual.

Every machine is supplied with an English hard copy of:

- electric, hydraulic scheme and pneumatic, where required;

- use and maintenance manual

Notes regarding the diameter of the produced grains:

The produced grains is not perfect spheroidal shape, with variable diameters depending on the exit holes of the die. The diameter of the grains drops varies according to the dies’ wear. If the die is worn and the diameter of the holes is no longer as it was originally, the diameter of the drops may vary. With a good state die it is possible to guarantee a diameter variation of about +/- 1.5mm for 80% of the produced grains.

Example: 10Kg of Au999 grains with an average diameter of 4.5mm will give about 8Kg of drops between 3 and 6mm and the remaining about 2Kg in grit with a diameter of higher or lower.

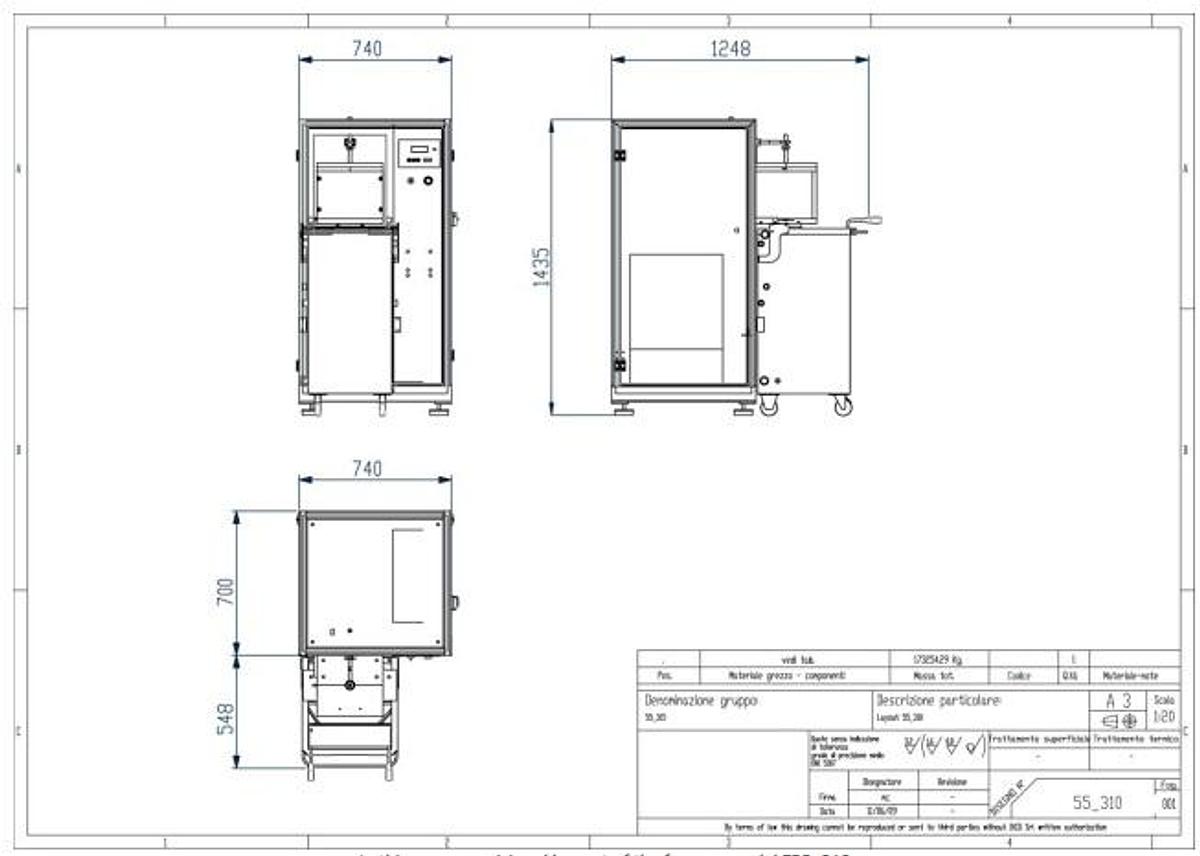

Specifications

| Manufacturer | IKOI |

| Model | Z55-310 |

| Year | 2025 |

| Condition | New |

| Stock Number | Z55-310 |

| Electric feeding | 400V – 3 phases - 50 Hz |

| Installed power of the furnace | 11 kW |

| Labor Frequency | ~6 kHz |

| Treatable metal | Gold Au 999 – Silver Ag 999 |

| Cooling Tank Capacity | 130 l |

| Cooling Tank Type of Water | Demineralized Water |

| Crucible Capability Au 999 | 14 kg |

| Crucible Capability Ag 999 | 8 kg |

| Maximum working temperature | ~1,250°C |

| Type of protective gas - Crucible - Die | Nitrogen |

| Feeding Nitrogen inlet pressure supply | 0,5 ÷ 1 bar |

| Feeding Nitrogen consumption | ~1,5 m³/h |

| Type of protective crucible gas | LPG |

| Feeding LPG inlet pressure supply | 30mBar |

| Compressed Air inlet pressure supply | 6 bar |

| Compressed Air flow rate | 0,2 Nl/h |

| Feeding water temperature (Min – max) | (Min – max) 19÷21°C |

| In-out water “Delta Temperature“ | 5°C |

| Feeding water consumption (min. 0,5 bar) | ~1.3 m³/h |

| Approximate weight | ~230 Kg |

| Size of the Furnace | ~740x1.248xh1.435mm |

| Suction required flow | ~ 0.1m/s |

| Environment temperature (min-max) | 10 ÷ 40 °C |

| Max relative humidity | 70% |