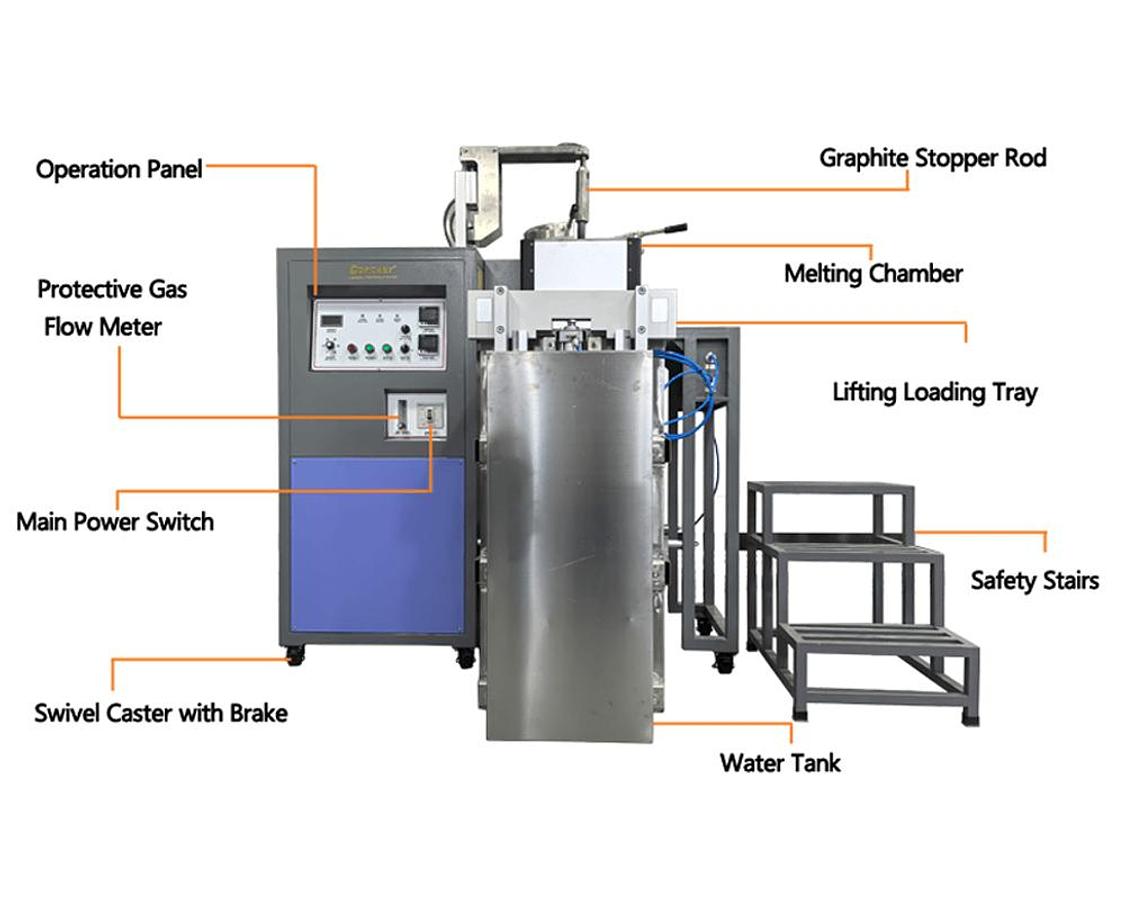

Grain Making Machine - Gold & Silver - 20Kg Capacity - With Automatic Lifting System

Grain Making Machine - Gold & Silver - 20Kg Capacity - With Automatic Lifting System

Location:Ex-Factory

Description

This 20Kg Model is Equipped with a Graphite Plug System, Stainless Steel Water Tank, and an Automatic Lifting System

The metal granulator is applied to produce various metal grains, such as gold, silver, K gold, copper, etc. The metal granulator includes three parts: the furnace, the water tank and the loading frame.

The molten metal will flow through the pure graphite comes with multihole at the bottom, and the whole granulation process is protected by inert gas argon or nitrogen, which minimizes the oxidation of metal.

The gold granulating machine & silver granulating machine are the most commonly used models. The metal granulator is equipped with an argon flow protection device. During the melting & granulation process, argon protection will be injected to prevent the oxidation of precious metals to the greatest extent. while if the customer plan to cast K gold grains, then we will recommend using vacuum granulating machine to prevent oxidation. click here to get more information about the vacuum metal granulator.

We can customized different metal granulator for customers according to different metals, different capacities, and different production efficiency for each client, please inquire.

Features:

- The granulator is used to produce high-quality precious metal particles and alloy particles with uniform color. The finished beads have no oxidation, high density and no pores, especially good spherical surface, uniform particles and stable color.

- The metal granulator comes with Inert gas protection system, which minimize the oxidation in the process of metal melting and casting, especially suitable for precious metals and alloy metals that are easily oxidized. It also reduce the loss of smelted metal and increase the life of the crucible.

- Applied with the Intermediate frequency induction heating technology, rapid melting speed, it takes about 15 minutes to melt one batch, and the casting time is about 15 minutes, which means that you will get high-quality metal grains within half an hour.

- The temperature can reach 1600°C, the granulation time is 20-30 minutes once, and the melting and granulation are completed in one. After the casting is completed, the pelletizing barrel is easy to take out.

- Pure graphite crucible comes with quartz jacket as protect, the multihole design at the bottom can act as breaker to make the molten metal cast into grains, what is more, It only takes 5 minutes to replace new crucible which is very convenient for the operator

- Special cooling water to prevent adhesion of metal particles and make particles more evenly formed.

- Metal granulator melting chamber and water tank can be designed separately or as an integrated unit, if there is not enough space for the user, we will recommend the integrated unit, which takes up less space.

- The detailed and complete self-diagnosis system and protection function ensure that the equipment failure rate is low.

- After the melt is completed, the casting speed is fast, making the metal particles smooth and smooth without sand holes.

- 2 Year Warranty

A gold silver granulator is a specialized machine used to produce high-quality gold granules, which are essential for applications in jewelry making, electronics, and industrial processes. One of the key components of a gold silver granulator is the **graphite crucible with a stopper rod**, which plays a critical role in controlling the flow of molten gold and ensuring consistent granule production. Below is an overview of the structure and functionality of this system.

1. Graphite Crucible

The graphite crucible is the core component of the gold granulator, designed to withstand high temperatures and chemical corrosion. It is made from high-purity graphite, which offers excellent thermal conductivity and durability. The crucible is responsible for holding and melting the gold or silver

- Material: High-purity graphite ensures minimal contamination of the molten gold or silver.

- Design: The crucible is typically cylindrical with a tapered bottom to facilitate the flow of molten gold.

- Heating: The crucible is heated using an induction Heating furnace to melt the gold or silver at temperatures above 1,064°C (1,947°F).

2. Stopper Rod System

The stopper rod is a precision mechanism that controls the flow of molten gold from the crucible into the granulation chamber. It consists of several key parts:

- Rod Material: The stopper rod is also made from high-quality graphite or ceramic to withstand high temperatures and resist wear. If the material is easily contaminated by graphite, we will also use boron nitride material as the plug rod

- Sealing Mechanism: The rod fits tightly into an opening at the bottom of the crucible, creating a seal to prevent molten gold from leaking.

- Actuation System: The stopper rod is connected to a manual or automated control system (e.g., pneumatic or electric actuator) that allows precise adjustment of the rod’s position. This controls the flow rate of the molten gold.

3. Granulation Chamber

Below the crucible and stopper rod is the granulation chamber, where the molten gold is transformed into granules. This chamber typically includes:

- Cooling Medium: Water is mostly used to rapidly cool the molten gold droplets, solidifying them into granules.

- Collection Tray: A tray or container collects the solidified granules for further processing. The granulator adopt the automatic lifting up tray to collect the granules, which can greatly reduce the cost the the production labor.

4. Control System

The gold granulator is equipped with a control system to regulate the melting and granulation process. This system includes:

- Temperature Control: Ensures the gold is melted at the optimal temperature.

- Inert Gas Flow Control: Adjusts the Inert Gas Flow Rate to get the most shinning and fine granules.

- Automation: Advanced granulators may feature automated controls for precise and repeatable operation.

5. Advantages of the Graphite Crucible with Stopper Rod

- Precision: The stopper rod allows precise control over the flow of molten gold, ensuring uniform granule size.

- Durability: Graphite components are highly resistant to thermal and chemical degradation.

- Efficiency: The system enables continuous and efficient production of high-quality gold granules.

Summary:

The graphite crucible with a stopper rod is a critical component of a gold and Silver granulator, enabling precise control over the melting and granulation process. Its robust design and high-temperature resistance make it ideal for producing consistent, high-quality gold granules. By understanding the structure and functionality of this system, manufacturers can optimize their granulation processes and achieve superior results.

Specifications

| Model | 39FL1 |

| Year | 2025 |

| Condition | New |

| Stock Number | 39FL1 |

| Electric feeding | 380V – 3 phases - 60 Hz |

| Installed power of the furnace | 40 kW Adjustable |

| Applicable Metals | Gold, Silver, Copper |

| Melting Time | 15 to 18 minutes per cycle |

| Max Capacity | 20KG Ag, 40Kg Au |

| Maximum Temperture | 1600 Degrees C |

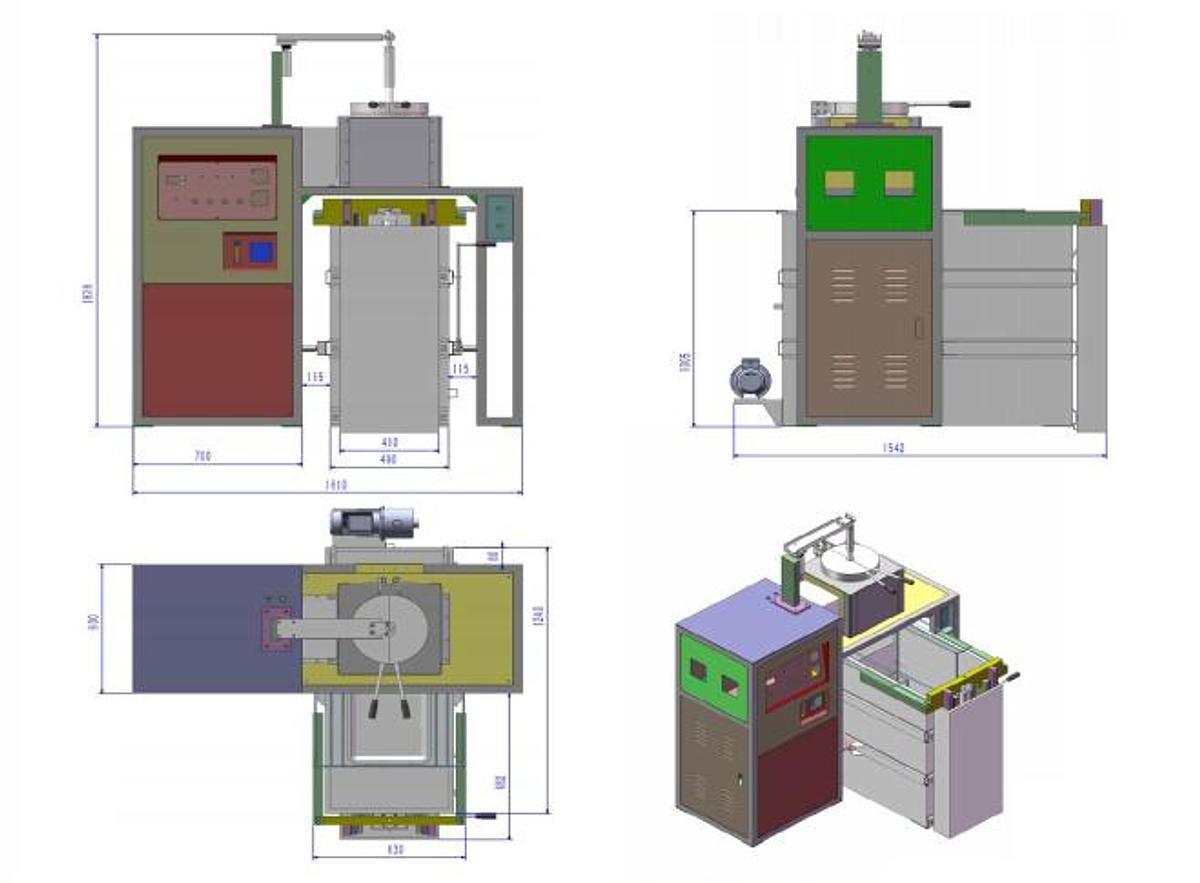

| System Size | 64" x 61" x 76" H |

| Estimated weight | 900 Lbs |